Abstract

As the global population continues to grow and dietary patterns shift towards higher protein consumption, traditional meat production faces mounting challenges. Lab-grown meat, a cutting-edge technology that allows meat to be cultivated in controlled laboratory settings, offers a promising solution. This article explores the emergence and potential of lab-grown meat as a sustainable and eco-friendly alternative. Lab-grown meat made possible through advancements in cell culture techniques, has gained regulatory approval in countries like Singapore and the USA. It represents a fundamental shift in meat production, with the potential to significantly reduce the environmental footprint associated with traditional livestock farming. Producing lab-grown meat involves cultivating muscle stem cells in bioreactors, leading to the development of muscle tissue that can be processed into various meat products. While cost remains a challenge, ongoing technological advancements aim to make lab-grown meat more affordable and accessible. One of the most compelling aspects of lab-grown meat is its positive environmental impact. It requires fewer resources, including land, water, and energy, and has the potential to mitigate deforestation, biodiversity loss, and greenhouse gas emissions. Lab-grown meat has been shown to reduce pollution and decrease water footprint significantly. Safety and health considerations also favour lab-grown meat, as it reduces the risk of pathogenic bacteria and allows for the customization of nutritional content. Despite its promise, lab-grown meat faces hurdles such as production costs, regulatory approvals, consumer acceptance, and addressing concerns within animal farming communities. However, it presents an exciting opportunity for the future of sustainable and ethical meat production.

Keywords: Lab-grown meat, Environmental footprint, Cell culture techniques, Ethical meat production

Introduction

According to estimates from the United Nations (World Population Prospects,2022), the global population reached approximately 8 billion as of November 15, 2022, and it is projected to reach 9.7 billion by the year 2050. This population growth poses significant challenges to various natural resources, particularly the availability of food. In addition, the increasing prevalence of obesity and diabetes can be attributed, to a large extent, to dietary factors. To address the increasing demand for food, and balance the nutritional requirements numerous alternative approaches and healthy diets have emerged worldwide. Diets that are high in protein, low in carbohydrates, and low in calories have gained popularity among individuals. In response, the food industry, particularly the meat industry, has experienced significant advancements, one such advancement is “cultured meat.” As the name says, this type of meat is grown in controlled laboratory settings, which resembles the processes used in the production of biopharmaceuticals. Most people prefer meat because of its essential nutrients/components and taste. The habit of consuming meat dates back to prehistoric times. Most of the countries are increasing the rate of global consumption of meat (Chriki & Hocquette, 2020). The meat consumption matrices reached over 328 million metric tons globally in 2021 and are expected to grow by 75% more. To meet the demand, the global livestock industry needs to grow; however, it suffers the challenges like limited land space, time to grow the livestock, water and air pollution. In addition, the excessive use of antibiotics for the growth of animals also has harmful effects on humans who consume the meat obtained from such animals. These concerns led to the emergence of an alternative for meat production “with low carbon and water footprint.” The advancement of cell culture techniques gave a solution to these issues by enabling the production of meat or animal products in laboratory settings. This is an alternative, faster, sustainable source for meat/animal products with an eco-friendly impact (Sinke, P et al, 2023). As technology continues to develop, production costs tend to decrease, potentially making cultured meat a mainstream food source soon.

Lab-grown Meat

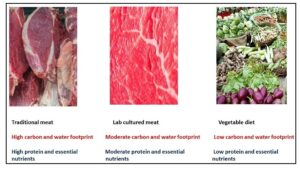

The idea that the meat on our plates is not from animals; instead, it is from the laboratories seems to be science fiction just a few years back, however, the advancements in cell culture techniques, made this a reality. Nowadays, meat can be produced in laboratory bioreactors, and two countries, Singapore and the USA, have approved lab-grown meat for human consumption. The idea of “cultured meat” gained prominence through the contributions of Dr. Jason Matheny in 2000 and Dr. Mark Post in 2013. Dr. Jason Matheny, promoted the development of cultured meat, through his publication (2000) and established an organization to advance research in lab-grown meat, i.e., New Harvest (Schonwald, J, 2009). The first edible lab-grown meat in the form of hamburger was made from beef through the efforts of Dr. Mark Post (Ismail, I et al, 2020). Later on, many biotech companies and startups worked in this direction, refining the production methods, making the meat as natural as possible and making it tasty by adding plant proteins. The lab grown burgers, and chicken nuggets are already in the market. By 2030, the lab-grown meat could make up a substantial portion of the global meat supply, potentially reaching 1% (https://www.mckinsey.com/industries/agriculture/our-insights/cultivated-meat-out-of-the-lab-into-the-frying-pan). The researchers created meat by cultivating minute samples of animal cells within controlled settings. Their efforts resulted in a product that could replicate the new dimensions of tasting and experiencing chicken breast or ground beef by manipulating cell density and shaping techniques. Some of the cultured meat prototypes, for example, “Super Meat,” were on sale in Tel Aviv, Israel; “Eat Just” a USA-based company selling lab-grown meat in Singapore. According to the information obtained from the Good Food Institute (GFI) and the Food and Agriculture Organization of the United Nations (FAO), lab-grown meat is a newly emerging substitute for traditional meat. It can impact natural resources like water, it significantly reduces water requirements for the production of meat compared to conventional meat and is more environmentally friendly with a lower carbon footprint as shown in Figure 1. It can shift consumer preferences, where individuals no longer prioritize expensive options like Wagyu beef, bluefin tuna, etc. It is assumed that with advancements in technology, even a small island could achieve the same level of affordability and efficiency in serving lab-grown meat dishes as a continent with vast grassy plains.

How is Lab-grown meat prepared?

Lab-grown meat is the result of years of research on stem cells and tissue engineering. Stem cells are most primitive, undifferentiated cells having unlimited proliferation capacities, found in the animals. These cell properties are exploited in making the meat in laboratories, and generally muscle “stem cells” are used for the purpose. To obtain the muscle stem cells, harmless biopsies are performed and culture them in controlled environments using bioreactors (Hocquette, J. F, 2016). The bioreactors provide sterile, warm conditions with a nutrient-rich medium required for cell growth, and these cells develop into muscle tissue. To make the muscle tissue, multiple types of cells grown on immovable scaffolds or beads coated with matrix proteins like laminin, collagen, or chitosan to create the desired texture. The bioreactors, equipped with scaffolds, make the cells grow as functional tissue; however, when cultured cells are more than 200 μm thick, oxygen and nutrients cannot penetrate the inner layer of cells, which causes those cells to die. At this point, strips of muscle are harvested from bioreactors and then processed for improving nutritional value, flavour, colour, and texture by adding ingredients, such as vitamins, iron, fat, seasonings, beet juice or heme for colour, and bread crumbs or other binding agents to hold the patties together. The protein composition of lab-grown meat primarily consists of contractile proteins, by tissue engineering, other proteins necessary for the texture, colour, and taste of the final product are expressed. For instance, myoglobin is an iron-carrying protein and is partially responsible for the pink or red colour of meat and enhances its taste; hence, myoglobin synthesis is encouraged before muscle harvest through transcriptional modulation ( Faustman et al., 2020). Sometimes, lab-grown meat is produced by 3D bioprinting, where more than one cell type is positioned precisely to bring the three-dimensional functional tissue that resembles the finished meat product (Mateti, T et al, 2022). It is imperative that specific details of the lab-grown meat procedure can vary depending on the technology, equipment, and type of animal cells used. The overview of the lab-grown meat procedure is shown in Figure 2.

Cost in which one could buy Cultured meat

One of the main hurdles in lab-grown meat production is its high cost of production. Many attempts are going on the technological advancements which potentially reduce the cost up to 99%. Mixing the plant-based proteins with lab-grown meat and production in large quantities significantly lowers production costs. Lab grown chicken combined with plant-based proteins is in the market (Company: Good Meat). Further, substantial investments in tens of billions of dollars are required to scale its production to even 1% of the global protein market. The upcoming decade is expected to primarily focus on demonstrating commercial viability and achieving modest market penetration

Impact on the Environment

Lab-grown meat could reduce the pressure on natural ecosystems and wildlife habitats, potentially leading to the restoration of biodiversity. This innovative approach is more efficient in decreasing deforestation, ecosystem degradation, mitigating greenhouse gas emissions, water pollution and land conversions. The metrics show that it reduces pollution by 93%, decreases water footprint by 78%, and if produced using renewable energy, it can result in 92% lower greenhouse gas emissions and up to 95% reduced land usage (Centre for Energy and Environmental Studies, Delft). Since it is produced in indoors, the external unfavourable conditions may not effect. For example, its lessens the risks of emerging infectious diseases principally associated with the storage, production, and consumption of animal products. Nevertheless, it is important to acknowledge that cultivated meat requires more energy to achieve a lower carbon footprint than conventional meat, it is crucial to incorporate renewable energy sources throughout the production process, including the supply chain, particularly for the production of necessary nutrients and other ingredients used in the culture medium. The companies involved in the lab-grown meat recognize the point, and it is imperative to integrate sustainable energy practices into their production methods. The Australian bioethicists give it a “double thumbs up” saying, “lab-grown meat stops cruelty to animals, better for the environment, safer, more efficient and healthier.”

Is the lab-grown meat safe and healthy?

Lab-grown meat offers several advantages when it comes to safety and nutrition. Conventionally sourced meat can have pathogenic bacteria and viruses like E. coli and Salmonella, which can cause serious diseases in humans, while lab-cultured meat significantly reduces the risk of these diseases (Chriki & Hocquette, 2020). In addition, lab-grown meat produced with specific nutritional contents like protein and minerals essential for a healthy metabolism. Many companies have the authenticity to alter the product’s nutritional profile, making a lower-fat and high protein steak through various recombinant technologies. It could also be a boon to public health by eliminating the need for factory-farmed animals and skipping the crowded and unhygienic agricultural operations that facilitate the spread of diseases.

Challenges:

Despite the potential benefits, lab-grown meat faces several challenges that must be overcome before it becomes a widely available and affordable product. The main scientific and engineering challenges the cultured meat industry faces is finding the best starter cells, mixing up a good “feed” to help them grow and finessing the logistics of manufacturing.

- Production cost: The 1st hamburger produced is the result of 2 years’ hard work and costs about US $325,000. The ingredients such as the medium, serum used in the production of lab grown meat are expensive. In addition maintenance of sterile conditions also adds production cost. The advancements in tissue engineering, production/manufacturing methods gives hope in lowering the production costs. Many companies working on wide variety of cells that can grow on different speeds or densities, and produce different textures or nutrient profiles. Some companies are working on the development of “immortal” cell lines, the Israeli firm Believer Meats reported the production of immortal chicken fibroblast cells (Pasitka et al 2023). These things not only cut short the production cost but also enhance human consumption’s acceptability, thereby making lab grown meat a sustainable product.

- High energy demand: Production of lab-grown meat requires large bioreactors (around 200,000L), which consume significant amounts of energy. However, many companies are working on the use of renewable energy sources and alternative sources of energy.

- Lab grown meat as Natural meat: Bringing the natural texure and savour taste to the lab grown meat so challenging as cells are cultured in vessels not as tissues. The meat flavors vary from one species to another, even in gender, age and farming conditions. Even within the same animal, even meat choices (muscle) depend on specific animal parts. So, a lot of consumer needs must be considered while preparing the cultured meat (Chriki & Hocquette, 2020). To achieve this few companies are trying to pair cultured meat with vegetable proteins and are trying to bring different flavors and textures.

- Regulatory approvals: Countries around the world follow strict regulatory frameworks. There are still concerns about how the technology will be regulated and approved for human consumption.

- Acceptance: Consumer acceptance of lab-grown meat is still uncertain, some may be hesitant to eat as they have produced artificially in a laboratory and has concerns about safety, taste, and texture.

- Religious beliefs: Navigating through the religious sentiments can be a delicate matter that can trigger debate, especially regarding specific guidelines and practices surrounding animal slaughter and meat preparation in certain faiths.

- Impact on animal farming communities: Lab-grown meat has the potential to disrupt traditional animal farming practices, which can have implications on those people who depend on animal farming for Engaging with and addressing the concerns of farming communities is essential in ensuring a smooth transition to lab-grown meat.

Lab-Grown Meat in Indian Scenario

The research area of culturing meat is still in its infancy in India. However, initial production attempts have already begun, paving the way for the anticipated availability of cultured meat products by 2025. India’s first lab-grown meat company, “Clean Meat,” established its laboratory at Jawaharlal Nehru University, New Delhi, and focuses on developing safe and harmless meat production methods (Srutee R et al, 2022). In addition, many prominent organizations are working on this emerging industry. The Centre for Cellular and Molecular Biology (CCMB), has teamed up with the National Research Centre on Meat (NRCM) to produce “Ahimsa Meat.” By leveraging cellular and molecular biology techniques, they aim to revolutionize the meat production process, providing consumers with a more ethical and sustainable meat option (Srutee R et al, 2022).The Humane Society International India (HIS, India) partnered with Good Food Institute (GFI) and CCMB to work on the production and promotion of lab-grown meat in India. They raise awareness about the benefits of clean meat and work towards establishing it as a viable and environmentally friendly alternative to conventional meat. Further, the state of Maharashtra and the Good Food Institute (USA) signed a memorandum of understanding in February 2019, for a strategic alliance to ensure a conducive environment for the cultivation of lab-grown meat to progress and thrive within the region (Srutee R et al, 2022; https://www.pashudhanpraharee.com/plant-based-and-lab-grown-meat-startup-an-indian-opportunity/ ). As India’s cultured meat industry continues to evolve, these collaborative efforts and research initiatives hold promise for a future where sustainable and ethical meat production can help meet the growing demand for animal protein while minimizing environmental impact and animal suffering.

Conclusion

As concerns over global food security grow, the environmental impact of conventional meat production becomes more evident, and slaughter-free alternatives are emerging as a promising solution for the future of food. Lab-grown meat exemplifies the cutting-edge field of tissue regeneration and engineering, representing a remarkable and comprehensive advancement in biotechnology. This innovative approach has the potential to address various aspects, including environmental sustainability, ethical considerations, and nutritional needs, serving as a viable substitute for traditional meat. Produced within sterile environments, it reduces the risk of contamination from diseases and chemicals. It impacts food security, the environment, and human health by reinventing a food system that will satisfy the requirements of meat products across the world in an ethical manner while keeping the environmental hazards in check. One of the conflicted aspects of this approach is the sustainability of animal farmers. It can’t replace animal farming completely and offers opportunities to collaborate with animal farmers with culture labs. In addition, plant-based lab-grown meat (Ismail, I et al, 2020) may address the concern of religious people addressing environmental pollution and meet the food demand. This novel food’s success and/or acceptability depend on its flavour and affordability. Lab-cultured meat has overcome several obstacles and is now commercially available as a secure, healthier protein with an enticing taste and aroma (similar to farmed meat). Low carbon emissions and low water usage address problems like global warming by lowering the GHG emissions of the entire food system. Therefore, substituting lab-cultured meat for farmed meat could benefit everyone, including vegetarians and meat eaters, and provide a solution to future global issues like food scarcity or other environmental. Although lab-grown meat has its benefits and drawbacks, the limitation of farmed meat can be an alternative meat source in the future.

Bibliography

- United Nations Department of Economic and Social Affairs, Population Division. (2022). World Population Prospects 2022: Summary of Results. UN DESA/POP/2022/TR/NO. 3.

- Chriki, S., & Hocquette, J. F. (2020). The myth of cultured meat: a review. Front Nutr. 2020; 7: 7.

- Sinke, P., Swartz, E., Sanctorum, H., van der Giesen, C., & Odegard, I. (2023). Ex-ante life cycle assessment of commercial-scale cultivated meat production in 2030. The International Journal of Life Cycle Assessment, 28(3), 234-254.

- Schonwald, J. (2009). Future fillet. University of Chicago Magazine, 101(5), 28-31.

- Ismail, I., Hwang, Y. H., & Joo, S. T. (2020). Meat analog as future food: A review. Journal of animal science and technology, 62(2), 111.

- https://www.mckinsey.com/industries/agriculture/our-insights/cultivated-meat-out-of-the-lab-into-the-frying-pan

- Hocquette, J. F. (2016). Is in vitro meat the solution for the future? Meat science, 120, 167-176.

- Faustman, C., Hamernik, D., Looper, M., & Zinn, S. A. (2020). Cell-based meat: the need to assess holistically. Journal of Animal Science, 98(8), skaa177. https://doi.org/10.1093/jas/skaa177

- Mateti, T., Laha, A., & Shenoy, P. (2022). Artificial meat industry: Production methodology, challenges, and future. JOM, 74(9), 3428-3444.

- Pasitka, L., Cohen, M., Ehrlich, A., Gildor, B., Reuveni, E., Ayyash, M., … & Nahmias, Y. (2023). Spontaneous immortalization of chicken fibroblasts generates stable, high-yield cell lines for serum-free production of cultured meat. Nature Food, 4(1), 35-50.

- Srutee, R., Sowmya, R. S., & Annapure, U. S. (2022). Clean meat: techniques for meat production and its upcoming challenges. Animal Biotechnology, 33(7), 1721-1729.

- https://www.pashudhanpraharee.com/plant-based-and-lab-grown-meat-startup-an-indian-opportunity/